Ceramic Lined Composite Steel Pipe, Ceramic Lined Pipe, Composite Steel Pipe

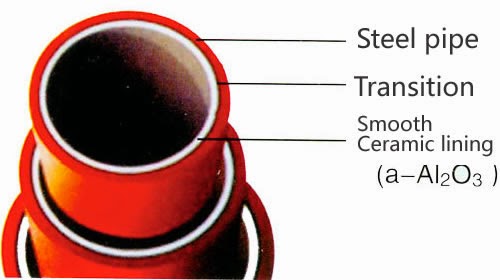

Ceramic lined composite steel pipe is made through self-propagating high-temperature synthesis (SHS) technique. The pipe consists of three layers: smooth ceramic lining (compact corundum), ceramic and metal transition layer and the outer seamless steel pipe. The combination of high rigidity of ceramic and high elasticity of steel gives the pipe unmatchable features as an abrasion resistant, heat resistant and corrosion resistant material for use in the fields of power generation, metallurgy, mining, and chemical industry etc.. It has many advantages over steel pipes, cast stone pipes, and steel-plastic compound pipes.

Features:

High abrasion resistant: Vickers hardness of the corundum lining is HV1100 to1500, as high as that of tungsten-cobalt hard alloys, and the abrasion resistance is 20 times as carbon steel pipes. Its rigidity is the highest among all oxides.

Corrosion resistant: Corundum is a neutral material, and is acid-proof and fouling -free.

Heat resistant: The pipe can work under circumstances of -50 to 800 degrees Celsius.

Convenient installation: It is much lighter than any other types of composite pipes, and can be welded or connected through flanges.

Cost effective: Ceramic-lined composite steel pipe can take the place of expensive stainless steel, titanium, nickel, cast stone or alloy pipes. Extended service life can also reduce maintenance cost.

Specifications:

- Pipe diameters: 50 to 630mm

- Elbow angle: 22.5, 45, 60, 90, 120, 135, 150 degrees, etc.

- Three way pipes: Y shaped, Y lateral and other special shapes

- Four way pipes: straight cross, reducing cross.

- Ceramic lining thickness (including transition layer): 3 to 8mm

- Ex-works length: less than or equal to 3m. Customized maximum length can be achieved by welding.

Technical performance parameters Ceramic Lined Composite Steel Pipe

Ceramic Lined Composite Steel Pipe is our continuous improvement after years of study introduced new wear-resistant pipes , the main technical performance parameters have the following:

Good wear resistance

Ceramic wear lining layer of the pipe due to the corundum ceramics (a-AL2O3), equivalent to 9.0 Mohs hardness up to HRC90 or more. So for metallurgy, electric power , mining, coal transportation and other industries grinding media have high wear resistance. Confirmed by the industrial operation : it is ten times the wear life of hardened steel or even several times .

Run a small resistance

Due to the inner surface of the pipe ceramic wear smooth, and never rust , not like the convex surface of seamless steel helix exists. After internal surface roughness of the test unit and water resistance characteristics of the test , the inner surface smoothness better than any metal pipes, clearing a drag coefficient of 0.0193 , slightly lower than seamless . Therefore, the tube has a running resistance and other characteristics , can reduce operating costs.

Corrosion-resistant, anti-fouling

Since the ceramic wear steel pipes ceramic layer (a-AL2O3), a neutral character. So with acid and seawater corrosion resistant , and also has anti-scaling and other characteristics.

We can also provide products of other customized sizes at your demand.

31.230416

121.473701