Wear-resistant alloy steel tubes for the base, lined with super wear-resistant alloy by centrifugal casting, metallurgical combine to form a solid body. LFC elbow vacuum casting process. Resistant alloy tube both excellent wear resistance, high temperature resistance and impact resistance, but also has good toughness, excellent thermal shock resistance to mechanical properties, welding performance, easy installation. Especially suitable for high temperature wear cold shock. Such as electric power, metallurgy, coal, mining, cement and other material handling industry. The product is compared with other wear-resistant pipe, long life, cost of investment economy.

Overall mechanical properties

|

抗弯强度

Flexure strength

|

抗拉强度

Tensile strength

|

延伸率

cpecific elongation

|

断面伸缩率

cross sedtion

Stretch ratio

|

冲出韧性αK

Impact

toughess

|

耐磨层硬度

thickness of

Wearable Layer

|

静水压试验压力

Hydrostatic

Testing pressure

|

|

MN/m²

|

MN/m²

|

%

|

%

|

J/cm ²

|

HRC

|

Mpa

|

|

>610

|

>700

|

5

|

5.1

|

>15

|

≥50

|

5.6-12.9

|

Performance comparison composite wear 16Mn steel pipe and concrete delivery

|

管型

Tube type

|

管型

Tube type

|

使用时间(天)

Service period(day)

|

输送物料(吨)

Material transported

|

磨损程度

attrition rate

|

提高寿命

improve lifespan

|

|

竖直管

vertical tube

|

16Mn管

|

10-15

|

12000/15000

|

需更换

|

22倍

|

|

复合耐磨管

|

355

|

264000

|

管口处磨损

|

|

弯管

Elbow

|

16Mn管

|

25

|

16000

|

需更换

|

12倍

|

|

复合耐磨管

|

244

|

192000

|

2mm

|

|

水平管

horizontal tubes

|

16Mn管

|

150-170

|

12000

|

更换

|

10.5倍

|

|

复合耐磨管

|

438

|

126000

|

磨损不明显

|

|

管型

tube type

|

管型

tube type

|

使用时间(天)

Service period(day)

|

提高寿命

improve lifespan

|

|

竖直管

Vertical tube

|

16Mn管

|

140

|

2.6倍

|

|

复合耐磨管

|

368

|

|

弯管

Elbow

|

16Mn管

|

90

|

6倍

|

|

复合耐磨管

|

540

|

|

水平管

horizontal tubes

|

16Mn管

|

154

|

2.6倍

|

|

复合耐磨管

|

400

|

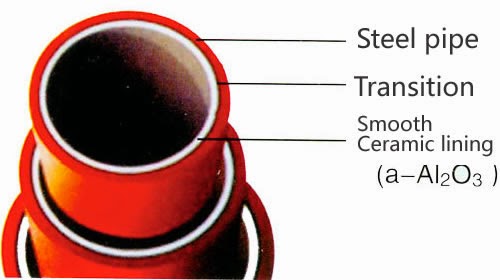

Wear-resistant alloy composite pipe Features

A good overall performance

Composite pipe outer wall with steel , lined with high-chromium alloy , the two formed a good metallurgical bond , both high alloy materials for wear and corrosion resistance properties, but also high mechanical strength and less high impact resistance , to solve a single material can be difficult to reconcile the contradictions and abrasion resistance welding , the material play to the best level of performance advantages, the use of safe and reliable.

2 high wear resistance

The composite wear layer composite pipe of high -chromium alloy , containing about 45% of the organization of the hard carbide M7C3 type , since this structure Ka rod- type carbide , and it has a high toughness ; while Ka macrohardness carbide micro- hardness is high (HV1500-1800), in the wear layer above HRC55 , so good wear resistance .

3 corrosion resistance , high temperature performance

Since the composition and structural characteristics Ka carbide substrate and the Cr content of the solid solution has a strong heat resistance, corrosion resistance , high temperature or corrosive environment can show good corrosion resistance, wear resistance.

4 advanced, stable composite technology

The wear-resistant pipe and elbow by LFC vacuum casting composite manufacturing process, namely F casting method , with the manufacturing process of composite wear-resistant pipe has the following characteristics :

( 1 ) The process is simple , easy to operate production yield.

( 2 ) Since the process is characterized by high precision tooling size , using an inner tube lined with real high vacuum in the tube by suction casting , so the product , the precise size , density is good.

( 3 ) using the method of vacuum casting process F resistant alloy composite pipe production and elbow, homogeneous and stable performance. Does not appear , cracks holes and other phenomena .

5 , good thermal shock performance

Since the inner tube composite wear , thermal expansion coefficient of the outer layer equivalent to a high level and constantly changing rapidly changing conditions occasions inner fragmentation does not occur , the phenomenon of early failure occurred small pipe system running resistance, beautiful appearance beauty .

6 . Transportation, installation and ease of use

Alloy composite pipe and elbow quick connector or flange can be welded directly mounted . As the fight against high- performance composite pipe , the pipe diversion occurs when a partial plugging free to percussion , arbitrary cutting , unloading change , installation , maintenance is very convenient.

alloy composite wear-resistant pipe applications

1 , power plants and coal transportation systems, dry ash conveying pipe ;

2 , Stone Coal power plant systems ;

3 , the other a powder pneumatic conveying systems ;

4 , hydraulic transmission systems and larger particle size slag slurry transportation ;

5, other mining material handling .

22.5 degree bend, Wear-resistant Alloy Composite 22.5 degree bend, Wear-resistant Alloy Composite bend, Wear-resistant Alloy Composite Pipe bend